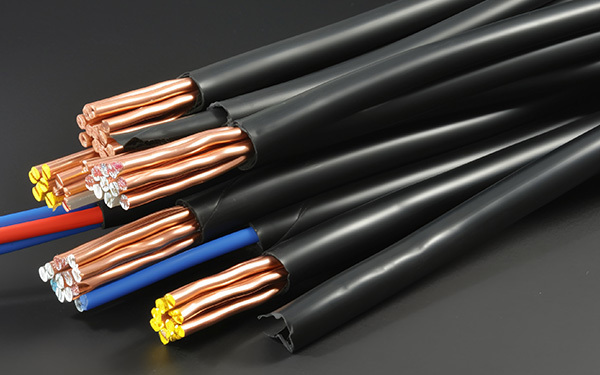

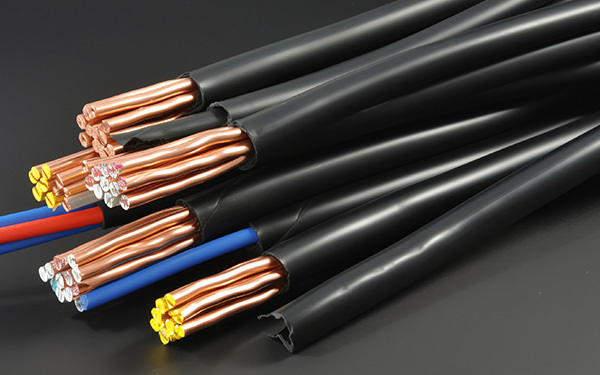

Cu-XHHW-2

Single conductor, 90℃ Wet/Dry. Insulated with chemically cross-linked polyethylene insulation.

key word:

Building Wire XHHW-2

Category:

Product Description

Building Wire XHHW-2

Description

Single conductor, 90℃ Wet/Dry. Insulated with chemically cross-linked polyethylene insulation.

APPLICATION:

1000/600 Volt Type XHHW-2 is intended for use as general purpose wiring for up to 1000 volt rated services in air conduit or other recognized raceways for services, feeders and branch circuit wiring as specified in the National Electrical Code at a maximum conductor temperature of 90℃ in wet or dry locations.

CONSTRUCTION

Conductors: Annealed stranded bare copper per ASTM B3 and B8. Class B Stranding per ASTM B8.

Insulation: thermoset cross-linked polyethylene

Colors: Available in black, white, red, blue, brown, orange, yellow, purple, gray, and green. Some colors are subject to economic order quantity.

STANDARDS & REFERENCES:

Copper Type XHHW-2 conductors comply with the following:

ASTM – B3 and B8

Listed per UL Standard 44

NEMA WC-70 (ICEA S-95-658) Construction Requirements

Gas & Oil Resistant II - All Sizes

CT Rated - Sizes 1/0 AWG and larger

Wet/Dry Locations (90℃)

Sunlight Resistant – Sizes 8 AWG and larger

RoHS Compliant

XHHW-2

| Conductor | Insulation thickness | Nominal O.D. | Approx. weight | Ampacity | DC Resistance at 20℃ | ||||

| AWG/kcmil | Min. No. | mm | mils | mm | kg/km | 60℃ | 75℃ | 90℃ | Ω/km |

| 12 | 7 | 0.76 | 30 | 3.8 | 38 | 20 | 20 | 20 | 5.35 |

| 10 | 7 | 0.76 | 30 | 4.4 | 57 | 30 | 30 | 30 | 3.35 |

| 8 | 7 | 1.14 | 45 | 5.7 | 94 | 40 | 50 | 55 | 2.1 |

| 6 | 7 | 1.14 | 45 | 6.6 | 142 | 55 | 65 | 75 | 1.32 |

| 4 | 7 | 1.14 | 45 | 7.7 | 218 | 70 | 85 | 95 | 0.83 |

| 2 | 7 | 1.14 | 45 | 9.1 | 336 | 85 | 100 | 115 | 0.522 |

| 1 | 18 | 1.4 | 55 | 10.4 | 428 | 95 | 115 | 130 | 0.413 |

| 1/0 | 18 | 1.4 | 55 | 11.3 | 533 | 110 | 130 | 145 | 0.328 |

| 2/0 | 18 | 1.4 | 55 | 12.4 | 664 | 125 | 150 | 170 | 0.261 |

| 3/0 | 18 | 1.4 | 55 | 13.5 | 830 | 145 | 175 | 195 | 0.207 |

| 4/0 | 18 | 1.4 | 55 | 14.9 | 1036 | 165 | 200 | 225 | 0.164 |

| 250 | 35 | 1.65 | 65 | 16.5 | 1237 | 195 | 230 | 260 | 0.139 |

| 300 | 35 | 1.65 | 65 | 17.8 | 1470 | 215 | 255 | 290 | 0.116 |

| 350 | 35 | 1.65 | 65 | 19 | 1704 | 240 | 285 | 320 | 0.0991 |

| 400 | 35 | 1.65 | 65 | 20 | 1946 | 260 | 310 | 350 | 0.0866 |

| 500 | 35 | 1.65 | 65 | 22 | 2410 | 280 | 335 | 380 | 0.0695 |

| 600 | 58 | 2.03 | 80 | 24.7 | 2916 | 320 | 380 | 430 | 0.0578 |

| 700 | 58 | 2.03 | 80 | 26.3 | 3390 | 350 | 420 | 475 | 0.0495 |

| 750 | 58 | 2.03 | 80 | 27.1 | 3622 | 385 | 460 | 520 | 0.0462 |

| 900 | 58 | 2.03 | 80 | 29.4 | 4328 | 400 | 475 | 535 | 0.0387 |

| 1000 | 58 | 2.03 | 80 | 31 | 4801 | 455 | 545 | 615 | 0.0348 |

+Allowable ampacities shown are for general use as specified by the 2014 Edition of the National Electrical Code Sections 310.15 and 240.4(D). Unless the equipment is marked for use at higher temperatures the conductor shall be limited to the following per NEC 110.14(C):

75℃ - When terminated to equipment for circuits rated over 100 amperes or marked for conductors larger than 1 AWG.

90℃ - THHN dry locations and THWN-2 wet or dry locations for ampacity adjustment purposes using NEC section 310.15.

Related Products

Message to us