Cu-THHN or THWN

General purpose wiring in accordance with the National Electrical Code, maximum conductor temperature of 90°C in dry locations and 75°C in wet locations, 600 volts, for installation in conduit or other recognized raceway. Also used for wiring of machine tools (stranded), appliances, and control circuits not exceeding 600 volts.

key word:

THNN or THWN

Category:

Product Description

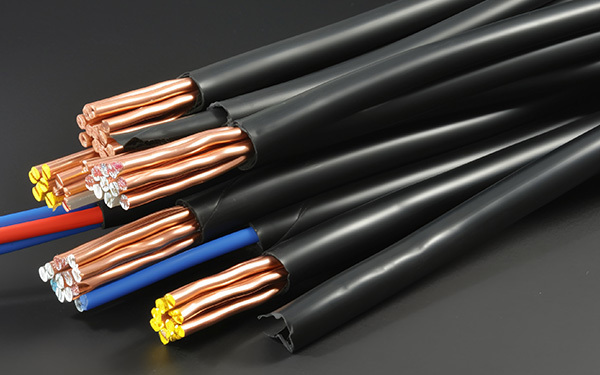

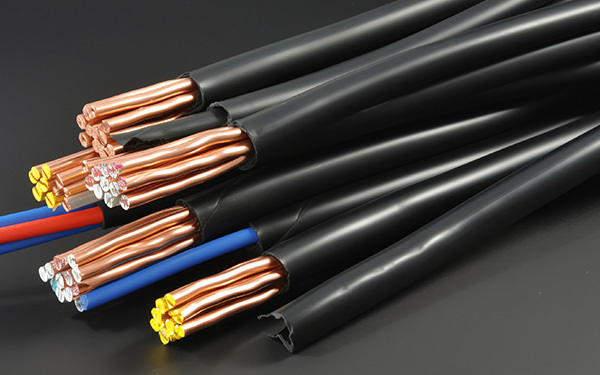

Building Wire-Cu-THHN or THWN

PVC Insulation, Nylon Jacket, 600 Volts

APPLICATION

General purpose wiring in accordance with the National Electrical Code, maximum conductor temperature of 90°C in dry locations and 75°C in wet locations, 600 volts, for installation in conduit or other recognized raceway. Also used for wiring of machine tools (stranded), appliances, and control circuits not exceeding 600 volts.

These conductors have multiple ratings. Depending upon the product application, allowable temperatures are as follows:

• THNN or T90 Nylon- Dry locations not to exceed 90℃

• THWN-2- Wet or dry locations not to exceed 90° C or locations not to exceed 75℃ when exposed to oil

• THWN- Wet locations not to exceed 75℃ or dry locations not to exceed 90° C or locations not to exceed 75℃ when exposed to oil

• TWN75- Wet locations not to exceed 75℃

• MTW- Wet locations or when exposed to oil at temperatures not to exceed 60° C or dry locations not to exceed 90℃ (with ampacity limited to that for 75℃ conductor temperature per NFPA 79)

• AWM- Dry locations not to exceed 105℃ only when rated and used as appliance wiring material

CONSTRUCTION

CU THHN/THWN(-2) conductors are made with soft drawn copper. Sizes 14 through 4/0 AWG use a combination-unilay stranding while 250 kcmil and larger sizes use a compressed copper stranding. The wire is covered with a tough heat and moisture resistant PVC insulation with an overall nylon jacket. Available in black, white, red, blue, purple, green, yellow, orange, brown, and gray. Some colors are subject to economic order quantity.

STANDARDS:

• ASTM B3: Annealed or soft copper wires.

• ASTM B8: Concentric Layered Copper Stranded Conductors.

• ASTM B787: 19 Wire Combination Unilay-Stranded Copper Conductors for Subsequent Insulation.

• UL 83: Wires and cables insulated with thermoplastic material.

THWN or THHN

| Conductor | Insulation thickness | Jacket thickness | Approx. weight | Ampacity | DC Resistance at 20℃ | |||||

| AWG/kcmil | No. | mm | mils | mm | mils | kg/km | lb/kft | 75℃ | 90℃ | Ω/km |

| 14 | 7 | 0.38 | 15 | 0.1 | 4 | 24 | 16 | 15 | 15 | 8.46 |

| 12 | 7 | 0.38 | 15 | 0.1 | 4 | 36 | 24 | 20 | 20 | 5.35 |

| 10 | 7 | 0.51 | 20 | 0.1 | 4 | 57 | 38 | 30 | 30 | 3.35 |

| 8 | 7 | 0.76 | 30 | 0.13 | 5 | 94 | 63 | 50 | 55 | 2.1 |

| 6 | 7 | 0.76 | 30 | 0.13 | 5 | 141 | 95 | 65 | 75 | 1.32 |

| 4 | 7 | 1.02 | 40 | 0.15 | 6 | 226 | 152 | 85 | 100 | 0.83 |

| 3 | 7 | 1.02 | 40 | 0.15 | 6 | 281 | 189 | 100 | 115 | 0.659 |

| 2 | 7 | 1.02 | 40 | 0.15 | 6 | 348 | 234 | 115 | 130 | 0.522 |

| 1 | 19 | 1.27 | 50 | 0.18 | 7 | 445 | 299 | 130 | 145 | 0.413 |

| 1/0 | 19 | 1.27 | 50 | 0.18 | 7 | 554 | 372 | 150 | 170 | 0.328 |

| 2/0 | 19 | 1.27 | 50 | 0.18 | 7 | 688 | 462 | 175 | 195 | 0.261 |

| 3/0 | 19 | 1.27 | 50 | 0.18 | 7 | 856 | 575 | 200 | 225 | 0.207 |

| 4/0 | 19 | 1.27 | 50 | 0.18 | 7 | 1068 | 718 | 230 | 260 | 0.164 |

| 250 | 37 | 1.52 | 60 | 0.2 | 8 | 1266 | 851 | 255 | 290 | 0.139 |

| 300 | 37 | 1.52 | 60 | 0.2 | 8 | 1506 | 1012 | 285 | 320 | 0.116 |

| 350 | 37 | 1.52 | 60 | 0.2 | 8 | 1747 | 1174 | 310 | 350 | 0.0991 |

| 400 | 37 | 1.52 | 60 | 0.2 | 8 | 1985 | 1334 | 335 | 380 | 0.0866 |

| 500 | 37 | 1.52 | 60 | 0.2 | 8 | 2463 | 1655 | 380 | 430 | 0.0695 |

| 600 | 61 | 1.78 | 70 | 0.23 | 9 | 2957 | 1987 | 420 | 475 | 0.0578 |

| 750 | 61 | 1.78 | 70 | 0.23 | 9 | 3667 | 2464 | 475 | 535 | 0.0462 |

| 1000 | 61 | 1.78 | 70 | 0.23 | 9 | 4847 | 3257 | 545 | 615 | 0.0348 |

+Allowable ampacities shown are for general use as specified by the 2014 Edition of the National Electrical Code Sections 310.15 and 240.4(D). Unless the equipment is marked for use at higher temperatures the conductor shall be limited to the following per NEC 110.14(C):

75℃ - When terminated to equipment for circuits rated over 100 amperes or marked for conductors larger than 1 AWG.

90℃ - THNN dry locations and THWN-2 wet or dry locations for ampacity adjustment purposes using NEC section 310.15.

Related Products

Message to us